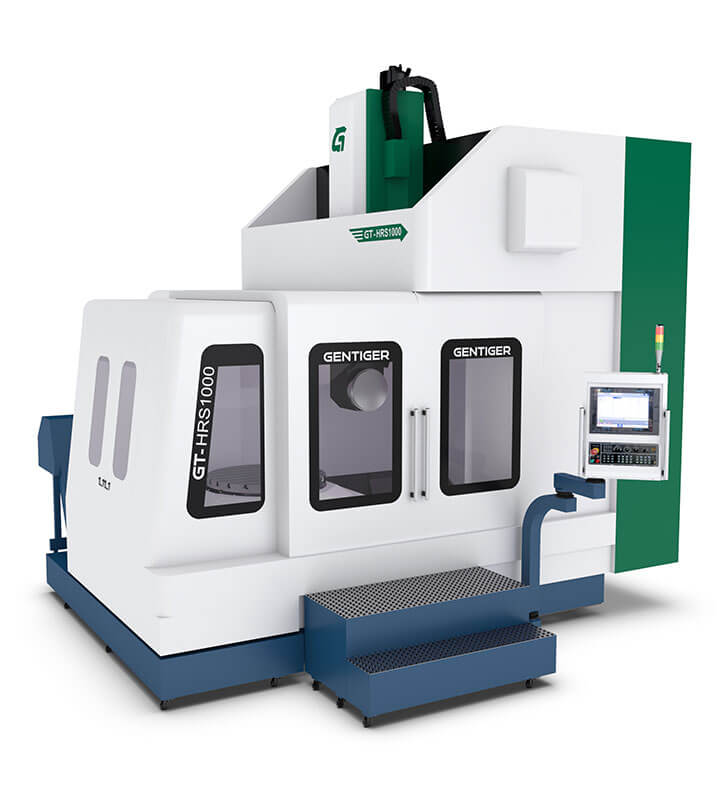

GT-HRS1000

Feature

Experience the Machining Stability

- With extra rigid double-column construction, high-speed spindle as well as high-cutting feed rates, the GT-HRS1000 has been fully recognized by the mold-making industry.

Optimal Structural Design

- Double column structure features ultra-high stability in high-speed machining.

- The table is independently installed on the base and fully supported by 3 roller-type linear guideways through the entire stroke, assuring maximum accuracy and dependability.

One-piece Constructed Columns

- The specially designed double-column, high-speed machine structure combined with a one-piece constructed column fully exhibits structural rigidity and stability during heavy cutting.

Three Axes Linear Guide Ways

- Roller-type linear guideways on three axes feature higher feed rates, resist heavier loads, and ensure superior dynamic accuracy and long service life.

- X axis is mounted with four linear guideways for superior rigidity.

Servo Motor Drives on 3 Axes

- Three axes are driven by powerful servo motors. Their power can reduce machining time for large molds and increase profitability.

Deformation Free

- All casting parts are stress-relieved and treated for lifetime accuracy without any deformation.

- Rapid feed rate on X, Y, Z-axis: 20 / 18 / 20 m/min.

- Cutting feed rate on X, Y, Z-axis: 20 / 18 / 20 m/min.

Specification

| MODEL | T18 |

|---|---|

| Travel (X / Y / Z) | 1,400 x 1,600 x 700 mm |

| Cutting Feed Rate | 20 / 20 / 20 m/min |

| Rapid Feed Rate | 20 / 20 / 20 m/min |

| Table area | Ø1000 mm |

| Max. Spindle Speed | 18,000 rpm |

| Type of spindle speed | Built-in |

| Bearing Lubrication | Oil-Air |

| Spindle Cooling | Water-cooling |

| Spindle Tapper | HSK-A63 |

| ATC capacity | 20 / 40 (Opt.) |

- Above specifications are subject to change without prior notice.

| B axis | Brand A:Tilting axis | Brand B:Tilting axis |

|---|---|---|

| Total Speed Reduction Ratio | 1:1 | |

| Max. Speed | 30~40 rpm | |

| Indexing Accuracy | ±5 sec | |

| Clamping Torque | 1,250 Nm | 650 Nm |

| Tolerant Cutting Force | 800 Nm | 280 Nm |

| Rotary Angle | ±115° | ±95° |

| C axis Table | Rotary Axis |

|---|---|

| Worktable Area | Ø1000 mm |

| Center Bore Diameter | Ø60H7 mm |

| Load Capacity | 2,500 kg |

| Total Speed Reduction Ratio | 1/1 |

| Max. Table Rotation Speed | 90 rpm |

| Indexing Accuracy | ±5 sec |

| Clamping Torque | 4,000 Nm |

| Tolerant Cutting Force | 2,310 Nm |

- Above specifications are based on Siemens controller, Heidenhain, Fanuc and Mitsubishi controllers are available.

- All specifications, design and characteristics are subject to change without prior notice.

Accessories

Standard Accessories

- Coolant tank

- Work lamp

- Tool box

- Coolant pump

- Coolant system

- Spindle cone air blast

- Air conditioner for electrical cabinet

- M.P.G

- Work end indication light

- Spindle thermo compensation function

- Caterpillar type chip conveyor and chip cart

- Central lubrication system

- Operation and maintenance manuals

- Leveling bolts and blocks

- Two chip augers beside work table

- Ethernet socket

- X / Y / Z axes optical scale

- B / C axes angle encoders

Optional Accessories

- CTS, Coolant through spindle

- Oil skimmer

- 40T Arm type magazine

- Automatic tool length measurement

- Automatic parts measurement device