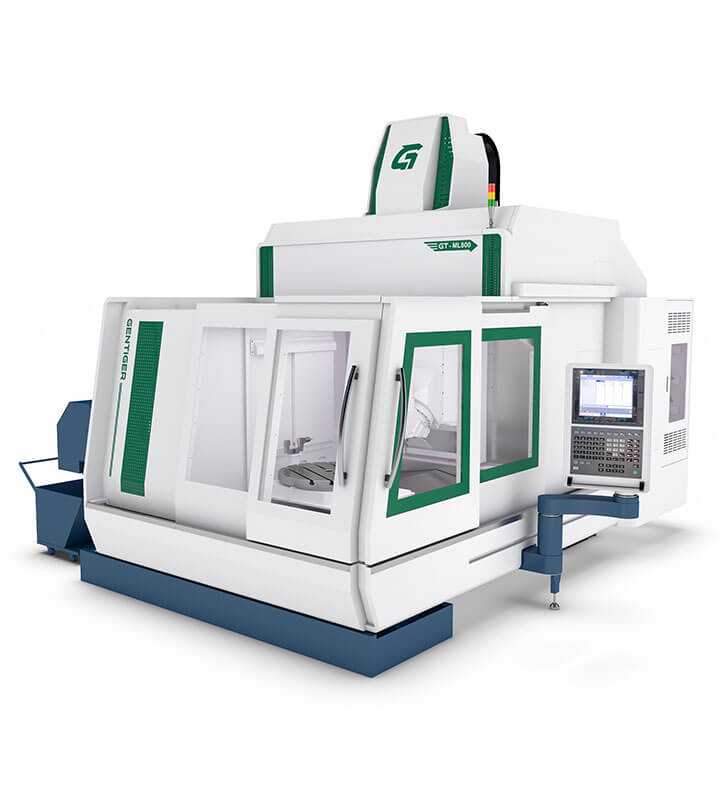

GT-ML800

Feature

- The closed type double column structure is excellent for 5 axis high speed machining, presenting optimal structure stability.

- Equipped with a vertical horizontal milling head (A axis) is combined with the rotary table (C axis) to perform turning and milling operations.

- The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

- With 5 axis simultaneous machinging, intricately shaped parts can be machined with only one setup.

- Equipped with a direct drive high precision rotary table with 5 seconds of positioning accuracy and 2 seconds of repeatability accuracy.

- Y axis is mounted with 3 linear guideways for increased stability during cutting.

- X/Y/Z axis are all equipped with linear scales, providing closed loop control and ensuring higher positioning accuracy.

- Chain type tool magazine, equipped with arm type tool change, providing fast tool change, smooth and stable motions.

Specification

| MODEL | ML800 |

|---|---|

| Travel (X / Y / Z) | 1000 x 1000 x 1000 mm |

| Cutting Feedrate(X / Y / Z) | 30 m/min |

| Rapid Feedrate (X / Y / Z) | 30 m/min |

| Table Area | Ø 800 mm |

| Max. Spindle Speed | 12,000 rpm |

| Spindle Type | Built-in |

| Bearing Lubrication | Grease |

| Spindle Cooling | Oli-Cooling |

| Spindle Tapper | HSK-T63 |

| Magazine loading capacity | 40 tools |

| C-axis Rotary Table | |

|---|---|

| Table diameter | Ø 800 mm |

| Max. Table Running Speed | 500 rpm |

| Rotating angle | 360 ° |

| Positioning accuracy | 5 sec |

| Repeatability accuracy | 2 sec |

| Loading capacity | 3000 kgs |

- All specifications, design and characteristics are subject to change without prior notice.

Accessories

Standard Accessories

- Coolant tank

- Work lamp

- Tool box

- Coolant pump

- Coolant system

- Spindle air blow system

- Air conditioner for electrical cabinet

- MPG

- M30 work end indication light

- Spindle heat compensation system

- Caterpillar chip conveyor and cart

- Central control lubricator

- Operation and maintenance manual

- Leveling bolts and pads

- Chip augers at both sides of table

- Internet function

- X/Y/Z axis optical scales

Optional Accessories

- Oil skimmer

- Oil fumes extraction

- Coolant through spindle

- Complex tool length measurement device

- Auto workpiece measurement device