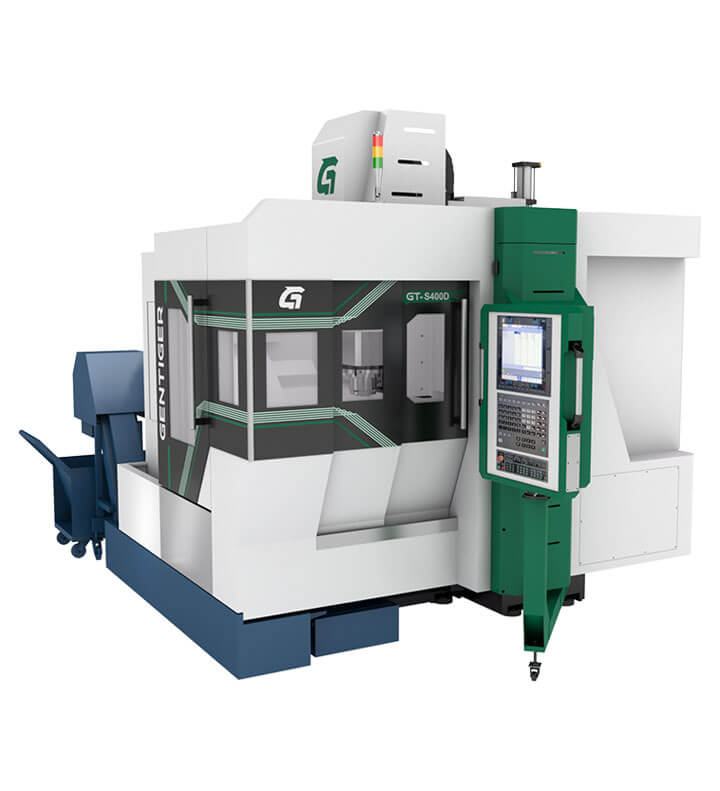

GT-S400D

Feature

Outstanding Machine Feature

- Strengthen the casting structure and improve the supporting strength.

- Table 45 degree design, easy clean and remove it to outside.

- The tool measurement device is located inside, mounted on the table casting, and moved together which will not interfere tool exchange and prevent chip pollution.

- Disc type tool magazine to improve efficiency.

- Unique design to facilitate iron filing cleaning.

- Reserve the automation equipment device interface.

- The wide side door could equip with automatic equipment and easy maintenance and cleaning.

- The interface is reserved in the center of the work-table, which can be installed with automation devices.

- Compact footprint.

Specification

| MODEL | T18 |

|---|---|

| Travel (X/Y/Z) | 600mm / 850 mm / 450mm |

| Cutting Feedrate | 20 m/min |

| Rapid Feedrate | 30 m/min |

| Table Area | Ø400 |

| Max. spindle speed | 18,000 rpm |

| Type of spindle motor | Direct drive |

| Bearing lubrication | Oil-Air |

| Spindle | Oil-cooling |

| Spindle taper | HSK-A63 |

| Atc capacity | 24 tools |

| B axis | Tilting axis |

|---|---|

| Max speed | 100 rpm |

| Indexing accuracy | ±3 sec |

| Clamping torque | 2,800 Nm |

| Rotary angle | ±180 |

| C axis table | Rotary axis |

|---|---|

| Worktable area | Ø400 |

| Load capacity | 300 kg |

| Max. table rotation speed | 200 rpm |

| Indexing accuracy | ±3 sec |

| Clamping torque | 800 Nm |

- Above specifications are based on Siemens controller, Heidenhain, Fanuc and Mitsubishi controllers are available.

- All specifications, design and characteristics are subject to change without prior notice.

Accessories

Standard Accessories

- Optical scales B/C axes

- Spindle air blow system

- Spindle oil cooler

- Oil-mist device

- Three-axis grease lubrication system

- Enclosed splash guard

- Caterpillar-type chip conveyor ( (for general machine tools chip removal)

- Coolant jets around the spindle

- M30 work end indication light

- LED work lamp

- Working end indication light

- Water gun at the operator's side

- MPG handwheel

- Ethernet support function

- Air conditioner for electrical cabinet

- Toolbox

- Leveling bolts and pads

- Operation manual

Optional Accessories

- ATC 30\40/60 tools

- Coolant through spindle 70bar

- Coolant through spindle

- Oil-mist collector

- Oli skimmer

- Linear scale for three axis

- Scraper-type chip conveyor (for tiny chips, such as copper, aluminum and cast iron chips)

- Transformer

- The workpiece measurement(with touch ball)

- The tool length measurement

- CE

Video