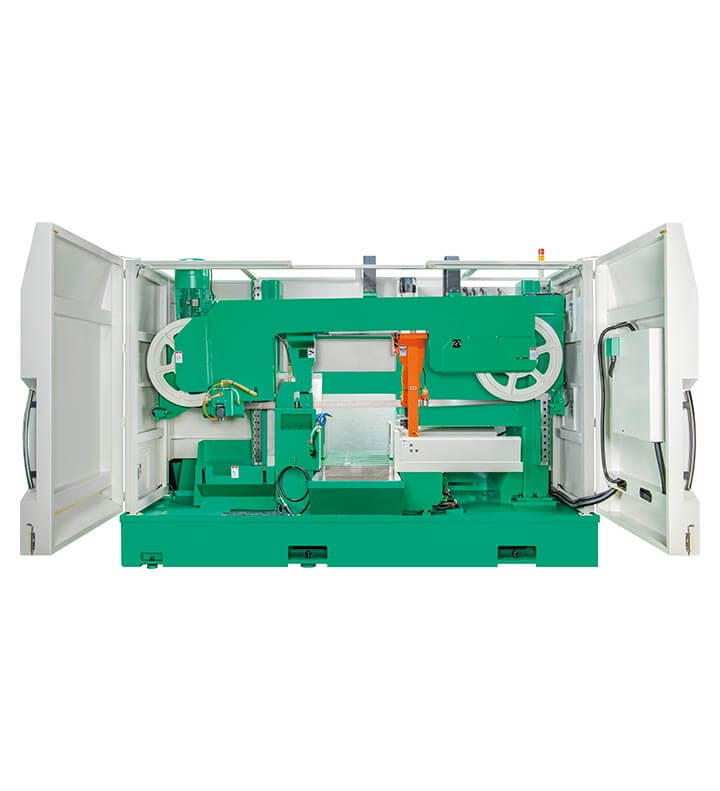

GT-A6H

Feature

Outstanding Machine Feature

- High rigid structure.

- Humanized operation control technology.

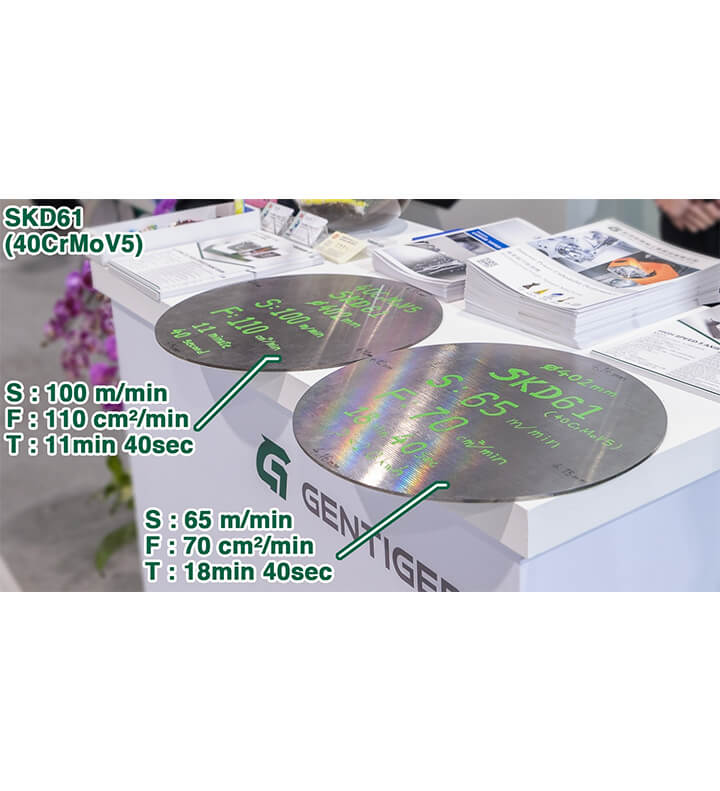

- Variable frequency adjustable stepless variable speed drive, precise feed, reduce wear and improve the life of the saw.

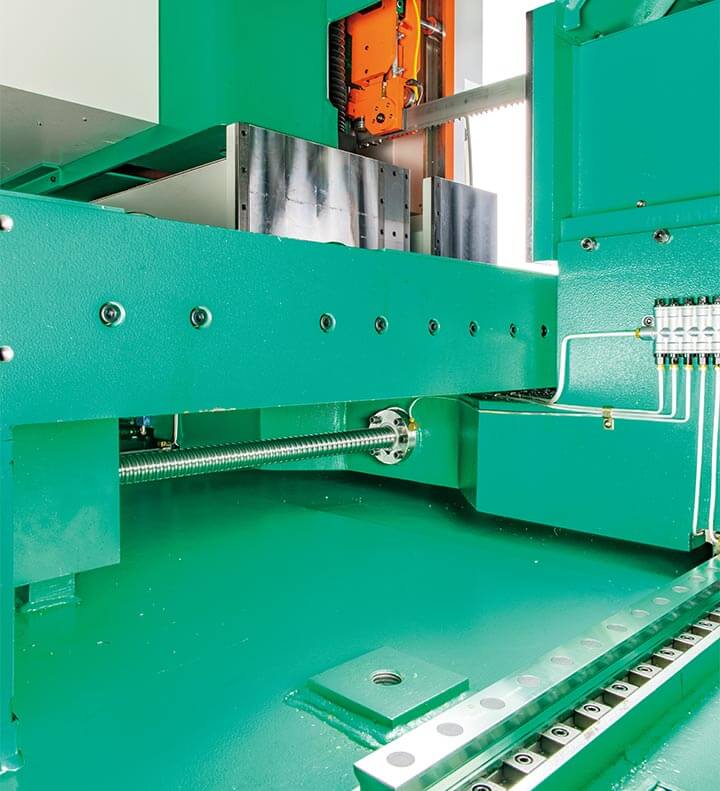

- One-piece roller frame with special vise to improve the smoothness of sawing.

- The double-column gantry arch is matched with the roller-type line rail slider, which ensures the fineness of the sawing material surface.

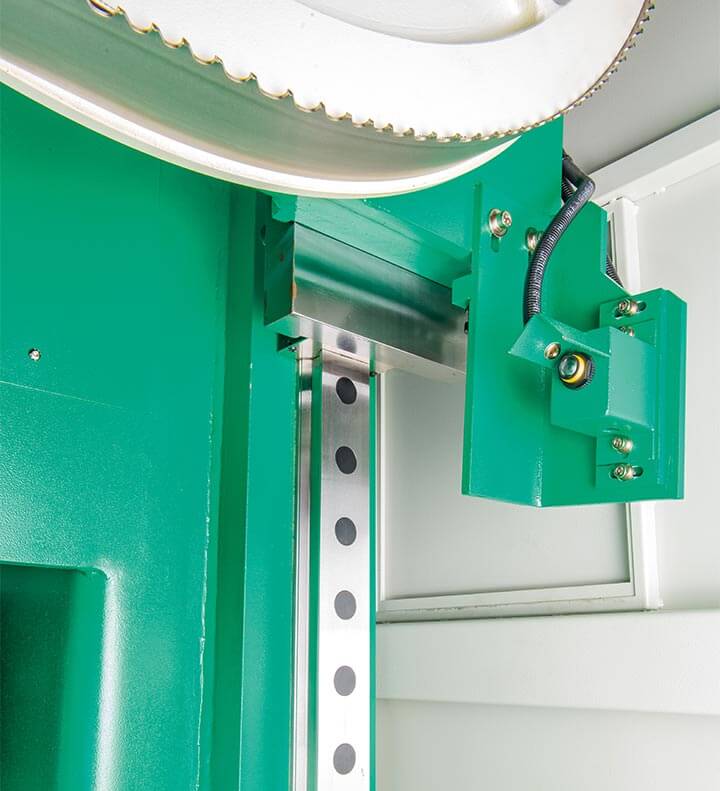

- The rotary encoder on the side of the driving wheel feeds back real-time control and compensation, making the transmission of cutting force more stable and reliable.

- Application of QR CODE for sawing processing to improve production efficiency.

Specification

| MODEL | GT-A6H | |

|---|---|---|

| Cutting Capacity | ● | 615 mm |

| ■ ▅ | 615 x 615 mm | |

| Saw Blade | Speed | 10 - 150 M/min. |

| Size | 8000 x 67 x 1.6 mm | |

| Tension | 液壓控制 | |

| Motors | Saw Blade | 15 kw |

| Hydraulic | 2.25 kw | |

| Coolant | 0.75 kw | |

| Wire Brush | 0.75 kw | |

| Pressure Washing | 1.75 kw | |

| Chip Conveyor | 0.187 kw | |

| Bar Feed | 3.55 kw | |

| Blade Feed | 3.55 kw | |

| Tanks | Hydraulic | 130 L |

| Coolant | 300 L | |

| Bed Height | 720 mm (28.3'') | |

| Dimension (L x W x H) | 3,800 x 2,300 x 2,500 mm | |

| New Weight | 9,000 kg | |

- Above specifications are based on Siemens controller, Heidenhain, Fanuc and Mitsubishi controllers are available.

- All specifications, design and characteristics are subject to change without prior notice.

Accessories

Standard Accessories

- Servo contrlled automatic feed system

- Variable blade speed controlled by High efficient inverter

- High quality NORD Motor

- Hydraulic blade tension

- Contactless band deviation monitor

- Blade hreakage detector and shutoff

- Laser controlled balde approach

- Hydraulic saw band clamping device

- Multiple design of anti-vibration structure

- Vises collocate linear decoder to capture material width

- Rotary control board with human machine interface

- Database for material sawing and saw band types

- Graphical dialogue operation control sawing mode

- Integrated bed surface and roller material feeding design

- Handwheel fine adjustment feed material sawing timing operation

- Roller-type linear guide

- High-pressure washer for band cleaning and chip removing

- High-efficient spiral and track-style chip conveyors

- Cutting data output

- Remote data reading connection

- CE-certificated full-boxed cover

- 2-meter roller stand

- Toolbox

Optional Accessories

- QR Code scan system

- Production automation connection

- Powered roller stand

Video