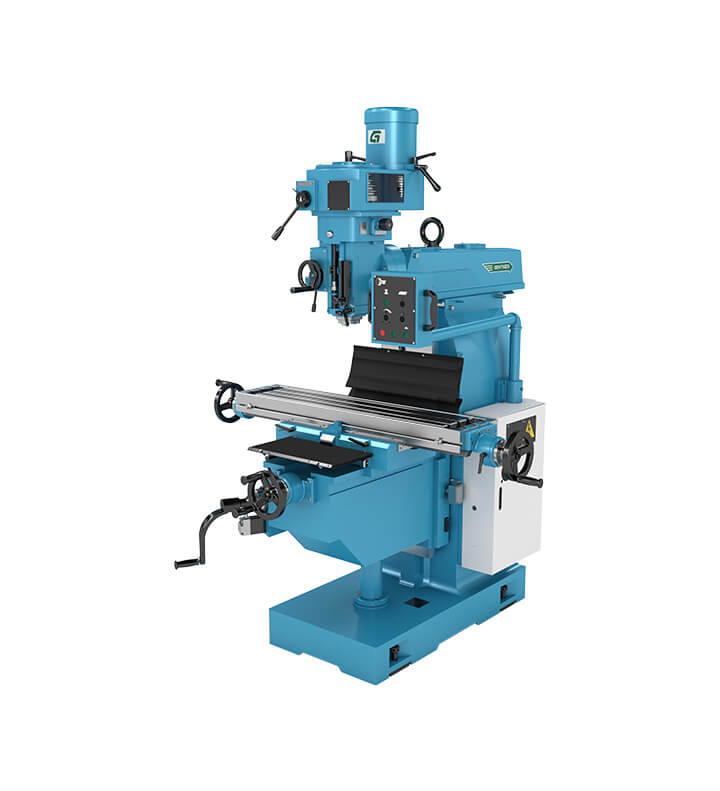

SHCM-97

Feature

Machine Features

- The turret type milling head is ruggedly constructed,combined with a heavy duty NST#40 spindle, making this unit excellent for heavy duty machining.

- The spindle is precision manufactured from quality alloy steel SCM-21, carburized, tempered, and precision ground for maximum material stability. The spindle runs on high precision P4 class bearings.

- Designed with an automatic forced lubrication system for the ground gears, clutch, and bearings inside the milling head, ensuring long service life of the head parts.

- FC-30 and FCD-35 high quality castings are tempered for maximum wear resistance and strain-free performance.

- The X and Y axis feeds are driven by a high precision C5 class preloaded, double nut ball screw. Each axis has a lock handle. Smooth feed, minimum backlash, superior positioning accuracy.

- The table slideways and upper surface are tempered and high frequency hardened. Both surfaces on the T-slot are precision ground, giving an accurate reference for machining.

- The body & base, and Z-travel slideway are one piece constructed.

- Automatic lubrication for X, Y and Z-axis slideways and feed screws ensures accurate motion for all parts. Lubrication interval is 60 minutes.

- Using a rough milling cutter (diameter 40mm, cutting depth 70mm, heavy cutting material S45C), the coin will not fall when it stands on the surface of the workpiece.

Specification

SHCM-97A

| MODEL | SHCM-97A |

|---|---|

| Spindle speeds | 75~3600 RPM 16 STEPS |

| Spindle nose taper | NST#40 |

| Head tilt (R & L) | 45° (R &L) |

| Overarm travel | 450 MM |

| Quill travel | 140 MM |

| Distance from spindle nose to table | 0~520 MM |

| Distance from spindle center to column | 165~615 MM |

| Automatic spindle feed speed | 0.035/0.07/0.14 MM (PER REV.) |

| Table area | 1200 x 260 MM |

| Longitudinal travel | 650 MM |

| Cross travel | 350 MM |

| Vertical travel | 360 MM |

| T-slot (Width x No. x Distance) | 16 x 3 x 65 MM |

| Quick vertical travel | 1150 MM |

| Spindle | 2.2 kW (3HP) |

| Knee | 0.75 KW (1HP) |

| Lubrication pump | 3W |

| Head lubrication pump | 13W |

| Machine dimensions | 2400 x 1610 x 2225 MM |

| Packing dimensions | 1700 x 1700 x 2100 MM |

| N.W. | 1680 KG |

| G.W. | 2060 KG |

SHCM-97VS

| MODEL | SHCM-97VS |

|---|---|

| Spindle speeds | 60~3600 RPM VARIABLE SPEED (Max. 4050 RPM) |

| Spindle nose taper | NST#40 |

| Head tilt (R & L) | 45° (R &L) |

| Overarm travel | 450 MM |

| Quill travel | 140 MM |

| Distance from spindle nose to table | 0~520 MM |

| Distance from spindle center to column | 165~615 MM |

| Automatic spindle feed speed | 0.035/0.07/0.14 MM (PER REV.) |

| Table area | 1200 x 260 MM |

| Longitudinal travel | 650 MM |

| Cross travel | 350 MM |

| Vertical travel | 360 MM |

| T-slot (Width x No. x Distance) | 16 x 3 x 65 MM |

| Quick vertical travel | 1150 MM |

| Spindle | 3.7 KW (5HP) AC INVERTED MOTOR |

| Knee | 0.75 KW (1HP) |

| Lubrication pump | 3W |

| Head lubrication pump | 13W |

| Machine dimensions | 2400 x 1610 x 2355 MM |

| Packing dimensions | 1700 x 1900 x 2100 MM |

| N.W. | 1740 KG |

| G.W. | 2140 KG |

Accessories

Standard Accessories

- Service tools

- Tool box

- Front and rear chip guard

- Spindle tapping device

Optional Accessories

- Halogen work lamp

- Cooling system

- Digital readout

- Spindle feed depth gauge

- Feed for X-axis ( POWER / GEAR / SERVO MOTOR)

- Feed for Y-axis ( POWER / SERVO MOTOR)

- Aluminum Cover

- Y-axis stainless chip guard

- Air Power Draw Bar