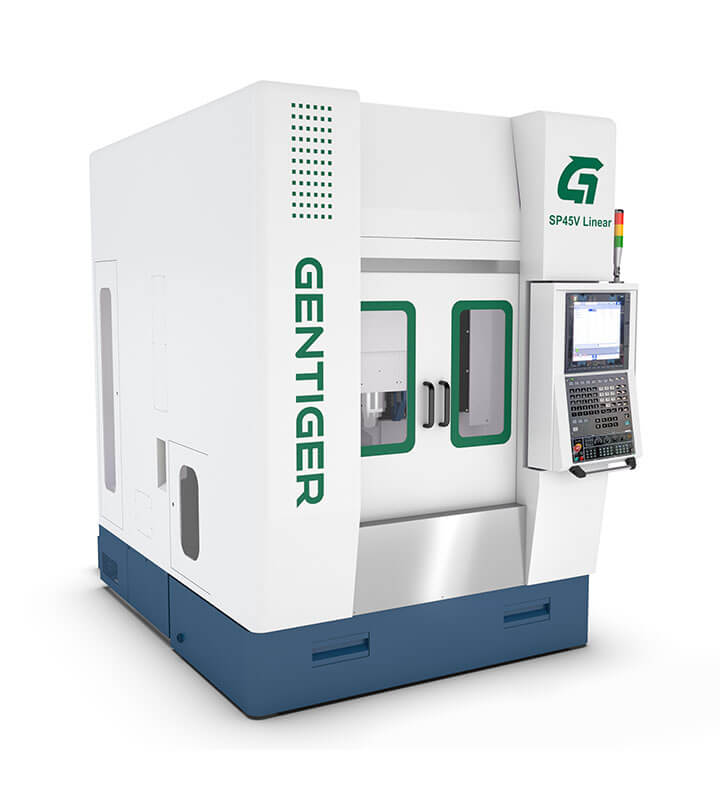

GT-SP45 Linear

Feature

Ultra High Precision Double Column Machining Center with Linear Motor Drive

- The best structural rigidity can resist cutting vibration, greatly improve tool life, and ensure cutting accuracy and efficiency.

- Three-axis linear motor drive, high speed, high precision, high efficiency, is suitable for precision molds and parts processing for medical equipment, semiconductors, optics, electronics, etc.

- Equipped with a comprehensive cooling system to reduce thermal deformation and ensure machining accuracy.

- Cutting feed rate on X, Y, and Z-axis: 60m / min

- Rapid feed rate on X, Y, Z-axis: 60m / min

Specification

| MODEL | S36E | ST42F |

|---|---|---|

| Travel (X / Y / Z) | 450 x 350 x 300 mm | |

| Cutting Feedrate(X / Y / Z) | 60 m/min | |

| Rapid Feedrate (X / Y / Z) | 60 m/min | |

| Table Area | 500 x 400 mm | |

| Max. Spindle Speed | 36,000 rpm | 42,000 rpm |

| Spindle Type | Built-in | |

| Bearing Lubrication | Oil-Air | |

| Spindle Cooling | Water-Cooling | |

| Spindle Tapper | HSK-E50 | HSK-E40 |

| Magazine loading capacity | 12 tools / 20 tools (Opt.) | |

- Above specifications are based on Siemens controller, Heidenhain, Fanuc and Mitsubishi controllers are available.

- All specifications, design and characteristics are subject to change without prior notice.

Accessories

Standard Accessories

- Coolant tank (including. dust collection tank x 2)

- Work lamp

- Tool box

- Spindle air blow system

- Chip air blow device

- Air conditioner for electrical cabinet

- MPG

- Work end indication light

- Full enclosed splash guard

- Central lubrication system

- Operation and maintenance manual

- Leveling bolts and pads

- Ethernet transfer function

- Spindle temperature compensation system

- Spindle cooler

- Internal working space cooling

- 3-axis linear ways cooling

Optional Accessories

- Oil skimmer

- Oil mist cooling system

- Auto tool measurement system

- Auto workpiece measurement device

- Coolant through spindle device