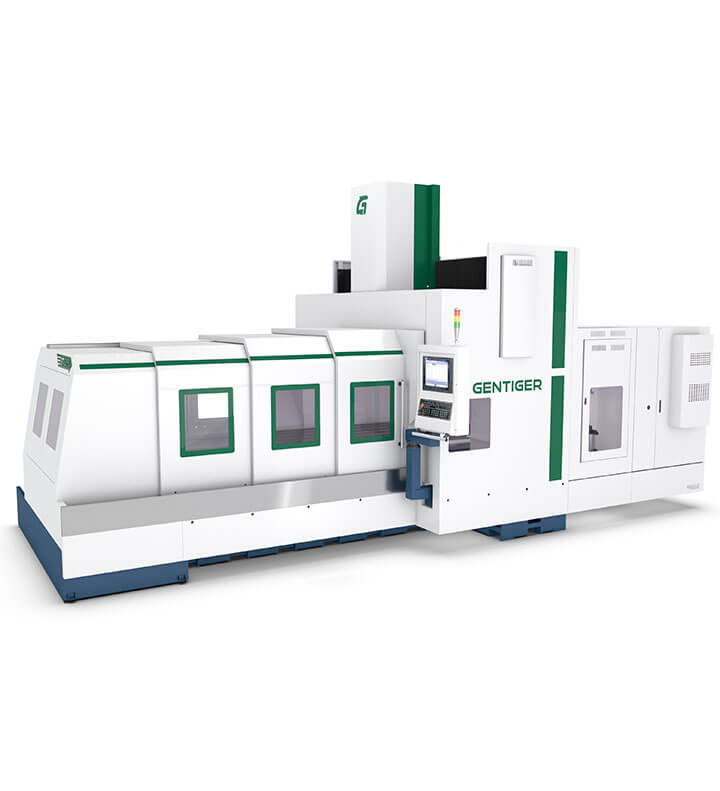

GT-2516V / GT-3016V

Feature

Optimal Machine Structure

- The model GT-2516V is a double-column structure designed for high-speed machining. The table is independently installed on the base and fully supported by 3 roller-type linear guideways through the entire stroke, assuring maximum accuracy and dependability. The columns are one-piece constructed for extra high rigidity.

Lifetime Accuracy

- All casting is stress relieved and seasoning treated for long-term accuracy and long service life.

Three Axes Linear Guide Ways

- Roller-type linear guideways on three axes feature higher feed rates, resist heavier loads, and ensure superior dynamic accuracy and long service life. The X-axis is equipped with 3 linear guideways for superior rigidity.

- Three axes are driven by powerful servo motors. Its strong power can reduce machining time for large molds and increase profitability.

- Three axes are equipped with Heidenhain optical scales.

- Rapid feedrate on X, Y, Z-axis: 20/18/20 m/min

- Cutting feed rate on X, Y, Z-axis: 20/18/20 m/min

- The cutter balance should be calibrated to within G2.5.

Specification

| MODEL | T10 | T15 | S24 |

|---|---|---|---|

| Travel (X / Y / Z) | 2500 x 1600 x 700 mm/ 800mm(opt.) 3000 x 1600 x 700 mm/ 800mm(opt.) |

||

| Cutting Feedrate(X / Y / Z) | 20 x 20 x 20 m/min | ||

| Rapid Feedrate (X / Y / Z) | 20 x 20 x 20 m/min | ||

| Table Area | 2800 x 1600 mm / 3000x1600 mm | ||

| Max. Spindle Speed | 10,000 rpm | 15,000 rpm | 24,000 rpm |

| Spindle Type | Direct Drive | Built-in | |

| Bearing Lubrication | Grease | Oil-Air | |

| Spindle Cooling | Oli-Cooling | Water-Cooling | |

| Spindle Tapper | BT-50 /BBT-50 | BT-40 /BBT-40 | HSK-A63 |

| Magazine loading capacity | 20 tools / 40 tools (OPT.) | ||

- Above specifications are based on Siemens controller, Heidenhain, Fanuc and Mitsubishi controllers are available.

- All specifications, design and characteristics are subject to change without prior notice.

Accessories

Standard Accessories

- Coolant tank

- Work lamp

- Tool box

- Coolant motor

- Coolant system

- Spindle air blow system

- Chip air blow device

- Air conditioner for electrical cabinet

- MPG

- M30 work end indication lamp

- Spindle cooling system

- Caterpillar chip conveyor and cart

- Central control lubricator

- Operation and maintenance manual

- Leveling bolts and pads

- Helix chip conveyors along side working table

- Network function

- X,Y,Z axis optical scale

Optional Accessories

- Oil and lubricant separator

- Oil-mist cooling system

- Auto tool measurement system

- Auto workpiece measurement system

- Coolant through spindle device